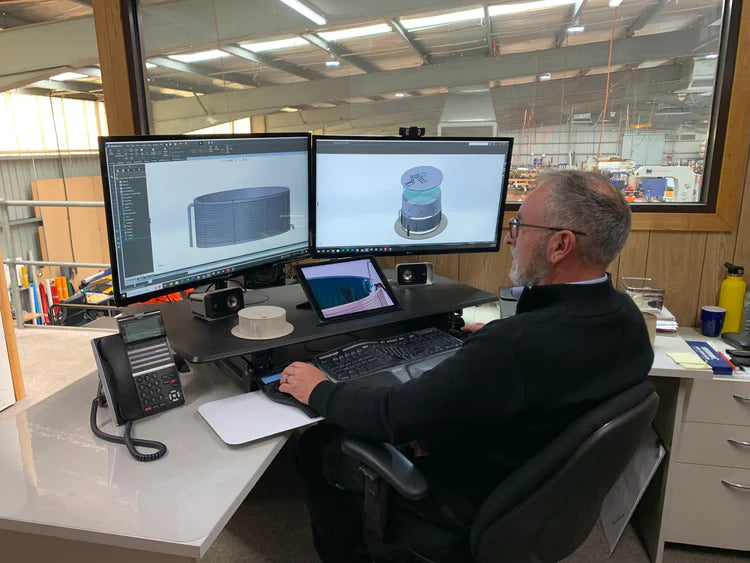

Design Capability

We know what it takes to bring a product to life. That’s why we’ve invested in advanced CAD software and the expertise of our in-house design team to create detailed, computer-generated cutting files. Every liner is carefully designed for continuity, consistency and appropriate fit, ensuring optimal performance and long-lasting reliability.

Specialists in Custom Manufacturing

We act as the production arm for numerous clients, manufacturing custom water tank liners expertly engineered to suit their unique tank structures and performance needs. Being flexible to meet our client’s requirements is important and we continually search for ongoing improvements. We can work from an existing design or help develop something new. We work on specific projects for customers and enjoy a mutual confidential, trusting, ethical and open relationship where we work with you to develop a product from concept to completion that can be marketed under your brand.

Contract Manufacturing

-

Capacity & Scope

Our regionally based Texas factory offers the greatest specialist production capacity in America for tank liner products. With highly trained specialized staff, we have scope to take on the largest of projects requiring accuracy and quality in manufacture.

-

Product Development

Our experienced product development team will start your project through consultation, before engaging our in-house industry experts in design, fabrication and material selection. We can rapidly prototype and bring an idea from concept to commercial production.

-

Innovation & Technology

Our commitment to innovation keeps us at the industry's forefront. We invest in expert teams through training and conferences, explore advanced materials, and integrate leading machinery for efficient, high-quality production.

-

Technical Textiles are in Our Blood

From our humble beginnings, technical textiles are in our blood. Our staff are fabric welding experts, with the ability to fulfil the most demanding requirements for industrial fabrics in the USA.

-

Material

We believe that exceptional product solutions begin with exceptional materials. Our dedication to fabric innovation, coupled with our strong partnerships with American and international manufacturers and suppliers, ensures that our industrial textiles used provide the ultimate protection and longevity for your application.

-

American Made

We are proud to be an American manufacturer, and support local jobs in Johnson City Texas. Knowing our final products sold to customers are amongst the best in the world.

Welding Equipment

Bartlett Manufacturing uses advanced welding equipment for liner fabrication, ensuring precision, consistency and seam strength. Many of our machines are custom-built or modified to suit our specific production needs, drawing on decades of in-house innovation and intellectual property. These enhancements allow us to achieve superior seam integrity and reliable performance across a wide range of technical fabrics.

Our welding systems use hot air, hot wedge and impulse technologies to produce liners that meet strict standards for potable water, chemical resistance and durability. By pairing advanced machinery with our proprietary processes, we deliver strong, consistent seams that keep tanks watertight for years and are trusted in demanding applications across the USA.

Precision Cutting Equipment

We utilize the latest advanced cutting equipment to deliver exceptional accuracy and repeatability in every liner we produce. Our cutting systems work directly from CAD designs, ensuring each panel is precision-cut.

By pairing world leading cutting technology with our in-house design expertise, we ensure that every liner is truly fit for purpose. The precise translation of design to finished product allows for consistent quality, reduced installation time and optimal performance across a wide range of tank sizes, shapes and applications.